Home > FAQ

Proper maintenance and lubrication allow better performance and extend the service life of the machine. Therefore, maintenance and inspection must be carried out on regular basis.

1. Danger

Danger

(1) Disconnect power during maintenance and inspection.

(2) Live maintenance must be carried out by specialists with protective measures taken.

2. Caution

Caution

Maintenance and inspection of equipment must be conducted by designated personnel.

1. Cleaning and maintenance of each shift

(1) Disconnect the power before cleaning the equipment to ensure the safety of both personnel and machine.

(2) Clean the exterior surface of equipment with a clean cloth which has been dipped into water with small amount of cleaner.

(3) Keep the die appearance clean and free of glue.

(4) Lubricate the lubrication points of machine by using manual lubrication pump before starting the machine. Please use proper amount of lubricant to prevent contamination of products due to spills.

2. Inspection and maintenance every month

(1) Oil lubrication should be made to the meshing gear, chain wheel and chain in the drive system of the machine. It is strictly forbidden to lubricate the flat conveyor belt and the synchronous belt.

(2) Check the tightness of the chain and belt of the transmission parts, and adjust them when necessary.

(3) Check the screws and nuts and tighten them as needed.

3. Maintenance and service every half a year

(1) Check the wearing parts and replace them when necessary.

(2) Check the transmission parts and belts for wear and replace them when necessary.

(3) Check whether all the joints of electrical and pneumatic lines are secure. Special care should be taken to check whether screws of the machine’s inner grounding terminal are firmly in place so as to ensure the continuous reliability of the grounding system. Dust electrical components by using proper amount of compressed air.

(4) Change the oil or grease of all the oiling points and oil tanks every 6 to 8 months of production. First drain all the old oil and grease, and then change the oil and grease after cleaning oiling points and oil tanks thoroughly with new grease.

4. Selection and application of lubricating oil

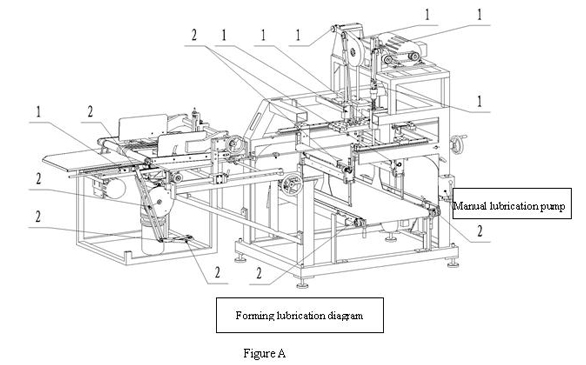

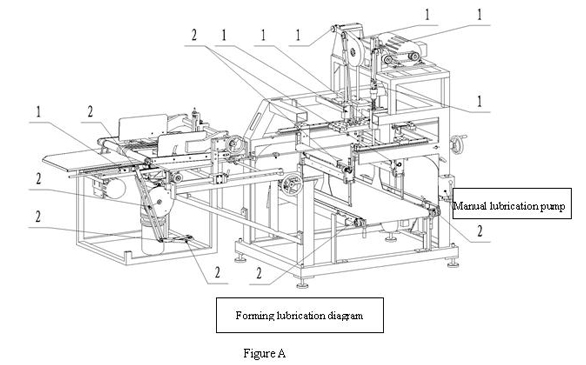

See Figure A: 1 refers to use N220~N320 lubricating oil, 2 means use 3# Li-based lubricating oil. Similarly, other parts and mechanism such as the linear slider and worm reduction gear should be lubricated with N220~N320 lubricating oil; gears, chain wheels and chains, bearing housings, cam rollers should use 3# Li-based lubricating oil. Oil lubrication should be made to the meshing gear, chain wheel and chain in the drive system of the machine by smearing. It is strictly forbidden to lubricate the synchronous belt and the flat conveyor belt.

1.

Danger

Danger (1) Disconnect power during maintenance and inspection.

(2) Live maintenance must be carried out by specialists with protective measures taken.

2.

Caution

Caution Maintenance and inspection of equipment must be conducted by designated personnel.

1. Cleaning and maintenance of each shift

(1) Disconnect the power before cleaning the equipment to ensure the safety of both personnel and machine.

(2) Clean the exterior surface of equipment with a clean cloth which has been dipped into water with small amount of cleaner.

(3) Keep the die appearance clean and free of glue.

(4) Lubricate the lubrication points of machine by using manual lubrication pump before starting the machine. Please use proper amount of lubricant to prevent contamination of products due to spills.

2. Inspection and maintenance every month

(1) Oil lubrication should be made to the meshing gear, chain wheel and chain in the drive system of the machine. It is strictly forbidden to lubricate the flat conveyor belt and the synchronous belt.

(2) Check the tightness of the chain and belt of the transmission parts, and adjust them when necessary.

(3) Check the screws and nuts and tighten them as needed.

3. Maintenance and service every half a year

(1) Check the wearing parts and replace them when necessary.

(2) Check the transmission parts and belts for wear and replace them when necessary.

(3) Check whether all the joints of electrical and pneumatic lines are secure. Special care should be taken to check whether screws of the machine’s inner grounding terminal are firmly in place so as to ensure the continuous reliability of the grounding system. Dust electrical components by using proper amount of compressed air.

(4) Change the oil or grease of all the oiling points and oil tanks every 6 to 8 months of production. First drain all the old oil and grease, and then change the oil and grease after cleaning oiling points and oil tanks thoroughly with new grease.

4. Selection and application of lubricating oil

See Figure A: 1 refers to use N220~N320 lubricating oil, 2 means use 3# Li-based lubricating oil. Similarly, other parts and mechanism such as the linear slider and worm reduction gear should be lubricated with N220~N320 lubricating oil; gears, chain wheels and chains, bearing housings, cam rollers should use 3# Li-based lubricating oil. Oil lubrication should be made to the meshing gear, chain wheel and chain in the drive system of the machine by smearing. It is strictly forbidden to lubricate the synchronous belt and the flat conveyor belt.

-

- Fully Automatic Box Making Machine (ZK-5540WL) ZK-WLH5540 automatic box making machinery is primarily applicable to packing materials like B, E and F corrugated papers, 12PT to 20PT ivory board and 250g to 645g grey board. This box making equipment is well-suited to product medium-grade paper boxes for shoes, food, toys, and daily necessities. ...

-

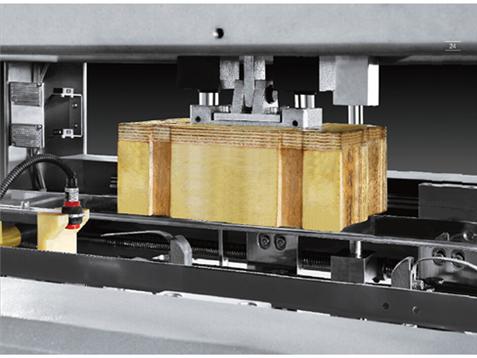

- ZK-900 Our ZK-900 rigid box making equipment is the most advanced and optimal equipment in China for high-grade rigid boxes (including cell phone box, shoe box, shirt box, cosmetics box, underwear box, food box, hardware box, gift box, etc.) production. ...

-

- Commodity box ZK5540WL commodity box maker is mainly applicable to such packing materials like B, E, F corrugated paper, 12PT to 20PT ivory board and 250g to 645g grey board. Boxes made by ZK5540WL commodity box maker can be utilized to package various commodities such as towel, soap, toothpaste, plastic paper, lighter and so on. ...